- info@kizwatech.com

- Mon - Sat: 8.00 am - 7.00 pm

We are creative, ambitious and ready for challenges! Hire Us

Over 10 years we help companies reach their financial and branding goals. Engitech is a values-driven technology agency dedicated.

411 University St, Seattle, USA

engitech@oceanthemes.net

+1 -800-456-478-23

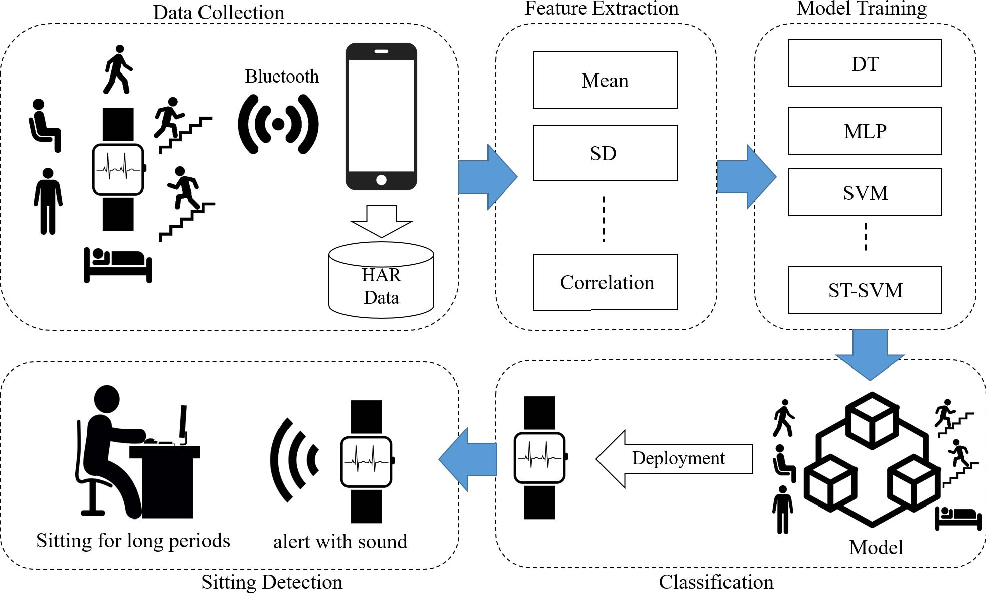

Kizwatech SHARP takes CNC machine monitoring to the next level by seamlessly integrating Supervisory Control and Data Acquisition (SCADA) systems with cutting-edge human activity recognition (HAR) technology. This powerful combination provides a holistic view of your CNC operations, empowering you to optimize workflows, improve data accuracy, and make informed decisions.

What is SCADA?

Supervisory Control and Data Acquisition (SCADA) systems act as the central nervous system of your factory, collecting real-time data from various sources, including CNC machines. This data includes:

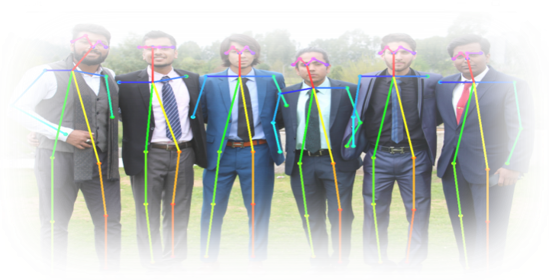

SHARP goes beyond traditional SCADA by leveraging the power of human activity recognition (HAR). Using state-of-the-art computer vision and deep learning algorithms, SHARP can analyze video footage from CNC machines and identify specific work activities performed by operators. This includes:

SHARP with SCADA and HAR empowers manufacturers to achieve:

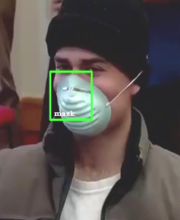

By integrating Human Activity Recognition with SCADA, SHARP enhances workplace safety and regulatory compliance. Real-time detection of unsafe behaviors or unauthorized access enables immediate intervention, reducing the risk of accidents and ensuring adherence to safety protocols.

SHARP's ability to monitor and analyze human activities in conjunction with industrial processes leads to improved productivity and efficiency. By identifying bottlenecks, optimizing workflows, and minimizing downtime, SHARP maximizes the utilization of resources and enhances overall operational performance.

With SHARP's comprehensive data logging and analysis capabilities, organizations gain valuable insights into human-machine interactions and process performance. By leveraging this data, stakeholders can make informed decisions, implement targeted improvements, and drive continuous optimization in industrial operations.

By automatically identifying and tracking work activities, SHARP helps you optimize CNC machine utilization and pinpoint areas for improvement.

Monitor operator activity against pre-defined organizational policies to ensure adherence to safety protocols and best practices.

Kizwatech SHARP is a revolutionary solution that bridges the gap between machine data and human activity. By leveraging the combined power of SCADA and HAR, SHARP provides a comprehensive view of your CNC operations, paving the way for a more efficient, productive, and profitable future.

SHARP represents the next evolution in SCADA technology, combining the power of real-time process monitoring with advanced Human Activity Recognition capabilities. By integrating human-centric insights into industrial automation, SHARP empowers organizations to achieve unprecedented levels of safety, productivity, and efficiency in today’s dynamic manufacturing landscape.