- info@kizwatech.com

- Mon - Sat: 8.00 am - 7.00 pm

We are creative, ambitious and ready for challenges! Hire Us

Over 10 years we help companies reach their financial and branding goals. Engitech is a values-driven technology agency dedicated.

411 University St, Seattle, USA

engitech@oceanthemes.net

+1 -800-456-478-23

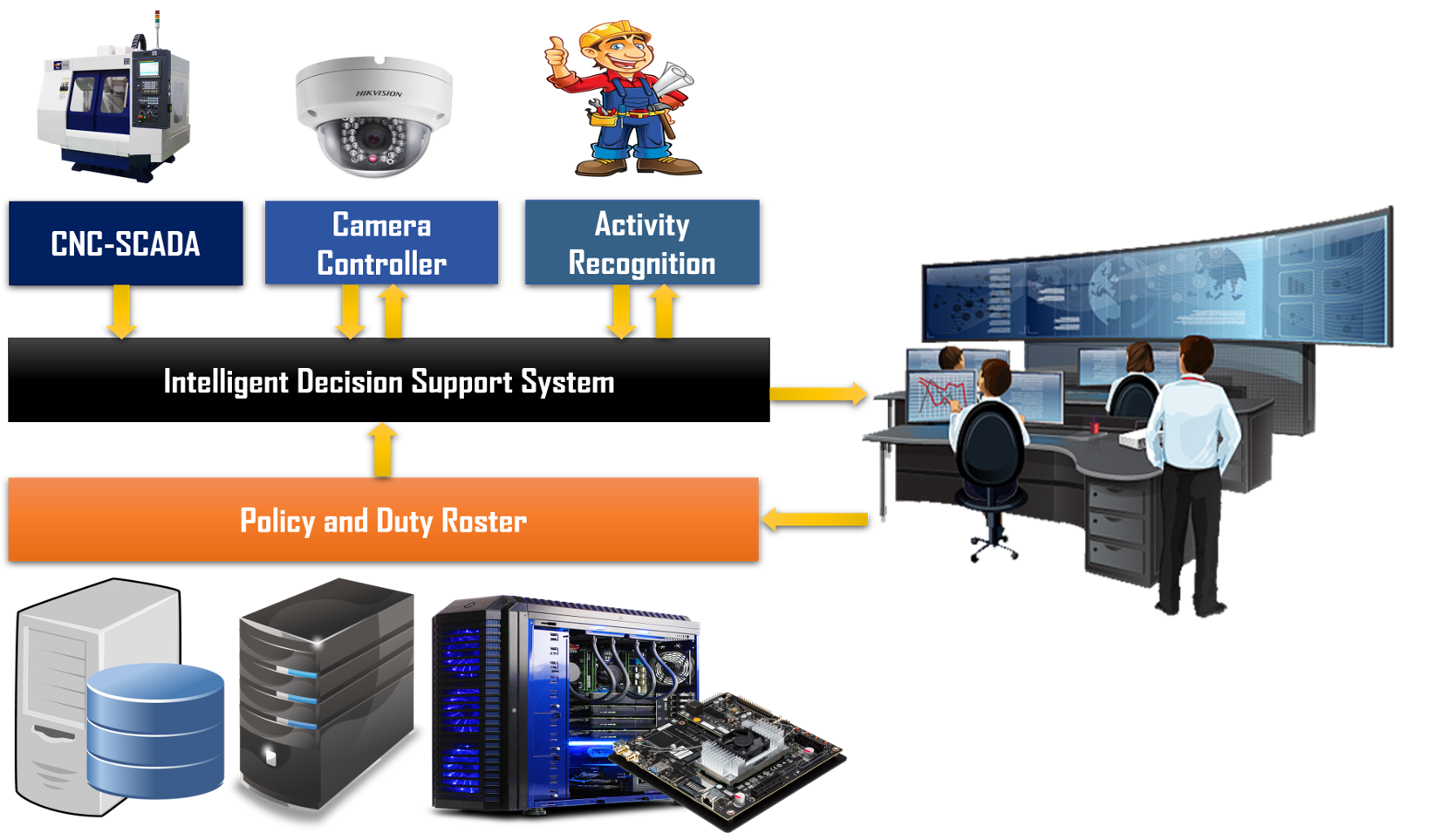

Kizwatech SHARP leverages Supervisory Control and Data Acquisition (SCADA) systems to provide a comprehensive monitoring solution for CNC machines. SCADA acts as the central nervous system of your factory, collecting real-time data from various sources, including CNC machines. SHARP integrates seamlessly with SCADA, unlocking valuable insights into machine operations and operator activity.

In today’s manufacturing environment, effective supervision and data acquisition are crucial for optimizing productivity and ensuring operational efficiency. KizwaTech introduces SHARP, a comprehensive solution that monitors SCADA parameters and evaluates operator activities on CNC machines based on pre-defined organizational policies. Leveraging state-of-the-art technologies such as computer vision and deep learning, SHARP revolutionizes the way manufacturing processes

SHARP goes beyond basic SCADA data collection. It analyzes the data using state-of-the-art computer vision and deep learning to identify specific work activities performed on CNC machines.

By analyzing machine status and visual cues, SHARP can accurately identify different work activities, such as loading materials, setting up tools, machining operations, and maintenance tasks.

SHARP automatically logs the start and stop times of each activity using computer vision, eliminating the need for manual data entry and ensuring accurate time tracking.

SHARP's camera system can be configured for both manual and autonomous mobility. The camera can be positioned manually to focus on specific areas of interest or programmed to move autonomously based on machine status, ensuring optimal coverage of all activities.

Collect and store data from sensors, PLCs (Programmable Logic Controllers), and other devices, facilitating analysis, reporting, and decision-making.

By identifying and tracking work activities, SHARP helps optimize CNC machine utilization and identify areas for improvement.

Kizwatech SHARP with SCADA offers a powerful solution for optimizing CNC machine operations. By leveraging the combined power of SCADA data analysis, computer vision, and deep learning, SHARP empowers manufacturers to achieve greater efficiency, improve data accuracy, and make data-driven decisions for a more productive and profitable operation.

With KizwaTech’s SCADA solutions, industries gain unparalleled control, visibility, and efficiency in their operations. From real-time monitoring to trend analysis, our SCADA systems empower organizations to optimize processes, reduce costs, and achieve operational excellence in today’s dynamic industrial landscape.